Hankook Alphatread

Extend Tyre Life. Reduce Costs.

Choose Sustainability.

-

Hankook Alphatread offers a premium hot cure retread solution for commercial fleets looking to reduce operating costs, maximize tyre life, and minimize environmental impact. Engineered using advanced Hankook tyre technology, Alphatread retreads deliver up to 100% of the mileage and performance of a new tyre—at approximately 70% of the cost.

Boost Your Fleet Performance with Hankook Alphatread

-

Maximize Tyre Life -

Maximize Tyre Life -

Up to 250% Total Tyre Life Built for Multiple Lives- 1st Life: New Tyre

- 2nd Life: Regrooved

- 3rd Life: Retreaded (Alphatread)

- 4th Life: Regrooved again

Hankook tyres are designed to be regrooved and retreaded, extending total mileage and maximising ROI over multiple use cycles.

-

Save Costs Without Sacrificing Performance

Save More, Travel Far

Save Costs Without Sacrificing Performance

Save More, Travel Far

- Up to 30–40% cost savings vs. new tyres

- Delivers 100% of the mileage of a new tyre

- Saves 70% of raw materials including rubber and steel

Alphatread’s hot-cure retreading technology reuses the original casing while maintaining premium performance—economical and environmentally conscious.

-

Improve Fleet Efficiency

Engineered for Extended Use

Improve Fleet Efficiency

Engineered for Extended Use

- Optimised casing durability

- Extra 5–8mm tread rubber added beneath pattern

- Regrooved tyres offer up to 10% more grip & traction

Resulting: Less downtime, longer-lasting tyres, and enhanced safety—supporting the productivity and profitability of your fleet.

The tread depth in a regrooved tyre is shallower than a new tyre

so it is more rigid. This rigidity reduces road friction and tyre rolling

resistance as well as less tyre wear leading to improved fuel efficiency.

Choose Alphatread. Choose Sustainability.

-

70% of raw materials saved

when retreading vs.

manufacturing a new tyre -

Up to 1.6 tons less CO₂

per vehicle set per year

-

19% less water

used in rubber production

-

2L fuel saved per 100km

with regrooved tyres

environmental responsibility.

Hankook Alphatread

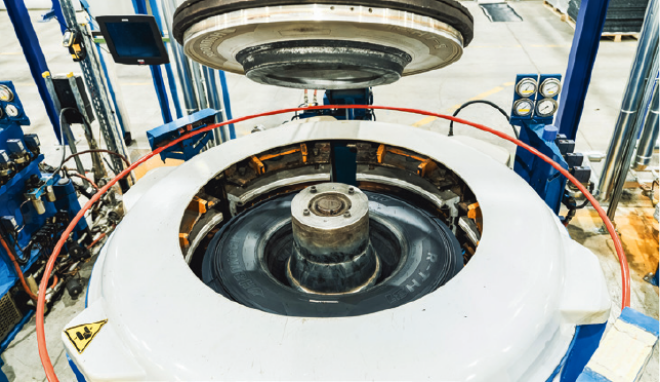

Premium Hot-Cure Retreading Process

-

01 Visual inspection

A thorough inspection of all casings is undertaken by a professional and highly experienced team.

-

02 Shearography machine inspection

Casings undergo a further detailed inspection with the Shearography machine to ensure they are perfect for the retreading process.

-

03 Tread removal

The tyre rebuild begins by removing all the remaining tread to expose any damage to the casing hidden by the rubber.

-

04 Damage removal

Next critical step is the complete removal of all the damaged elements of the casing.

-

05 Damage repair

Any damaged casing plies and other damages are repaired.

-

06 New tread rubber

Now the casing is ready to have the tread rubber reapplied.

-

07 Tyres cured for 1 hour at 160°C

The curing press creates the new tread and sidewall and the finish on the Alphatread tyre is "as new". This is the identical process used for Hankook premium tyres.

-

08 Final inspection

To guarantee a performance close to our new premium tyres, 100% of Alphatread production is both manually and pressure inspected before approved for sale.

Explore Hankook Alphatread retread tyres

Can't find what you're looking for?

Have more questions?

Our team is here to help — get in touch today.

-

Contact Sales

Contact Sales

Need tailored advice or pricing?

Our tyre specialists are ready to assist your fleet needs. -

Find a Dealer

Find a Dealer

Locate your nearest authorized Hankook Alphatread dealer.

Use our interactive map to connect with a local expert. -

Download Brochure

Download Brochure

Get full product details, specs, and application guidance.

Download the official Alphatread brochure.