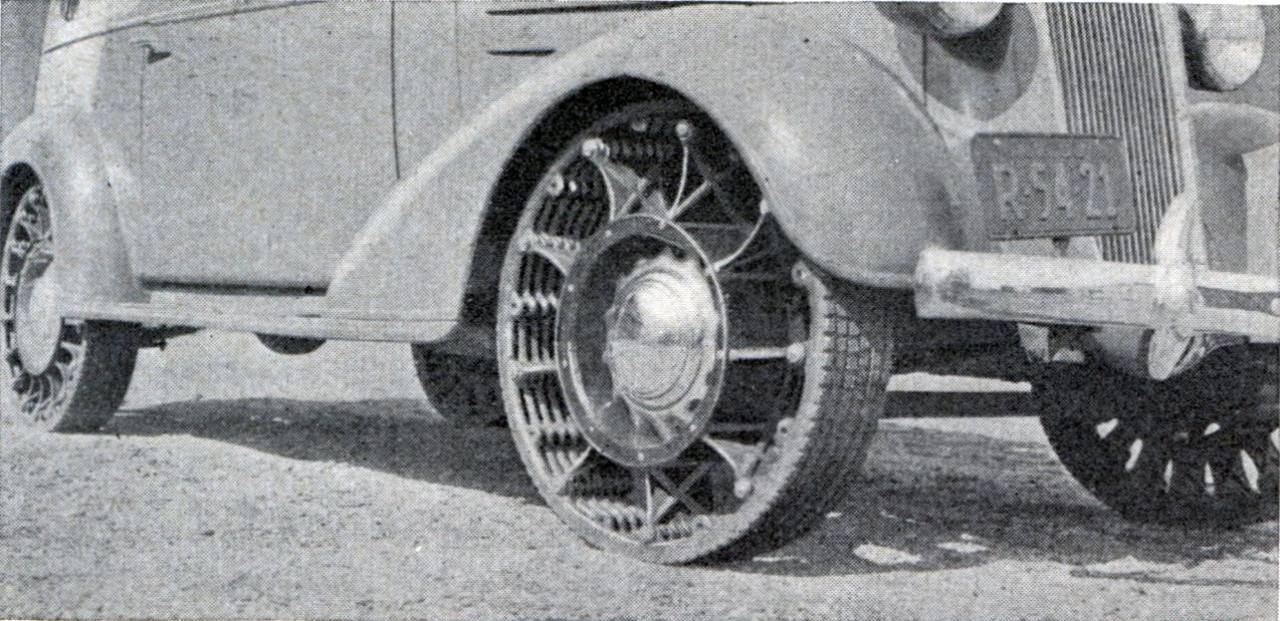

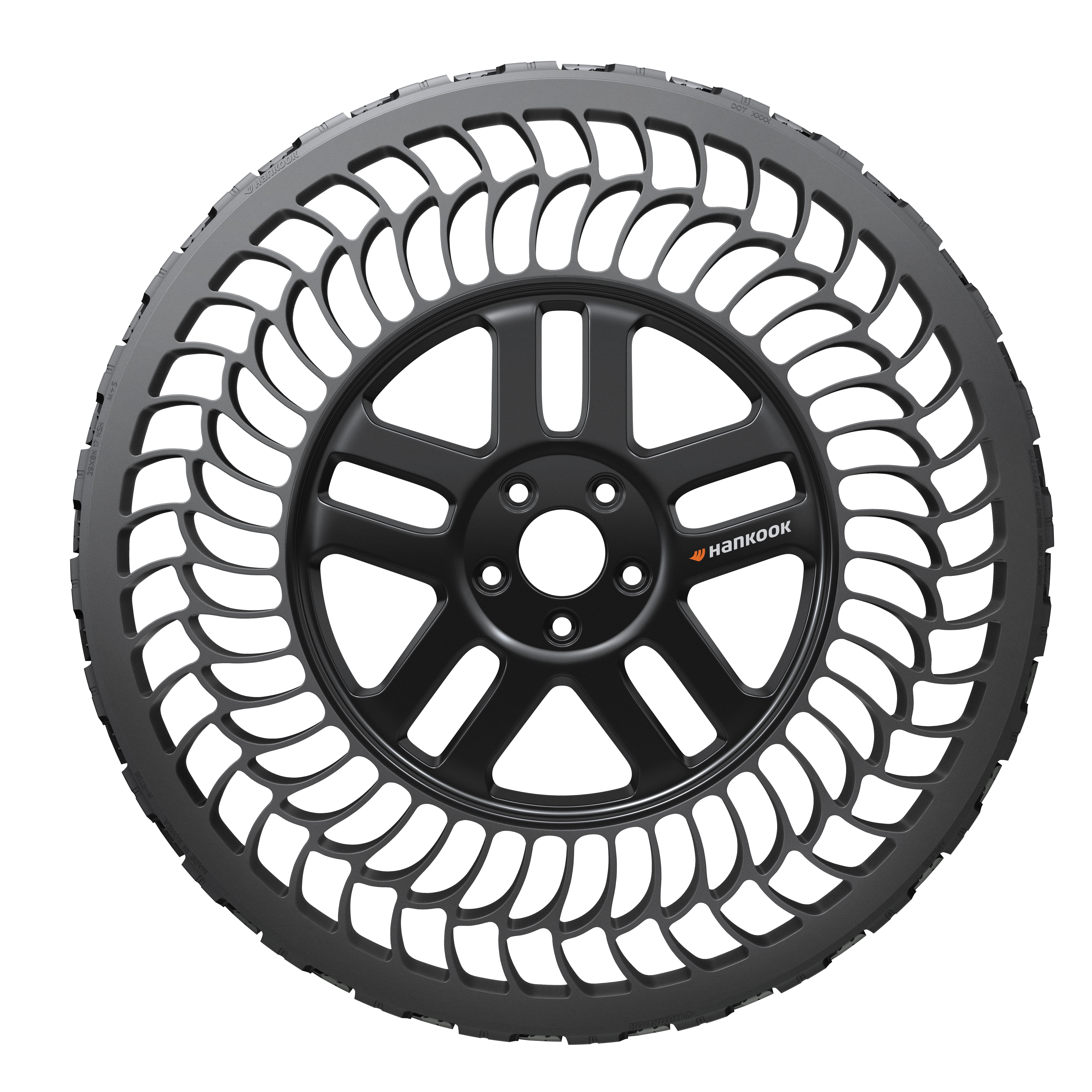

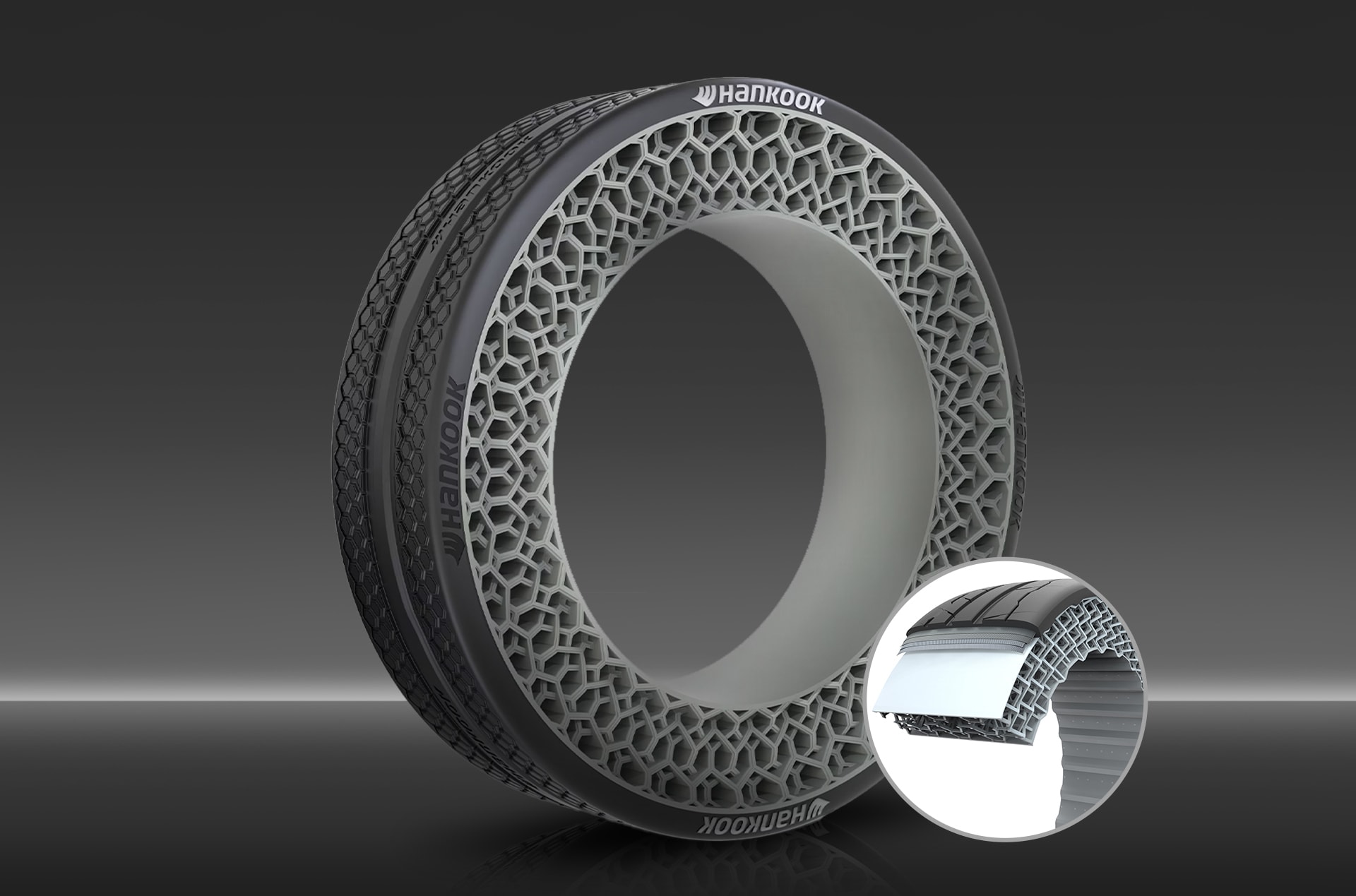

Tyres play a critical role in the performance and safety of an automobile. Today, pneumatic tyres are taken for granted as they are used in numerous modes of transportation, which started with bicycles in the late 19th century. But, tyres of the future may no longer need air.

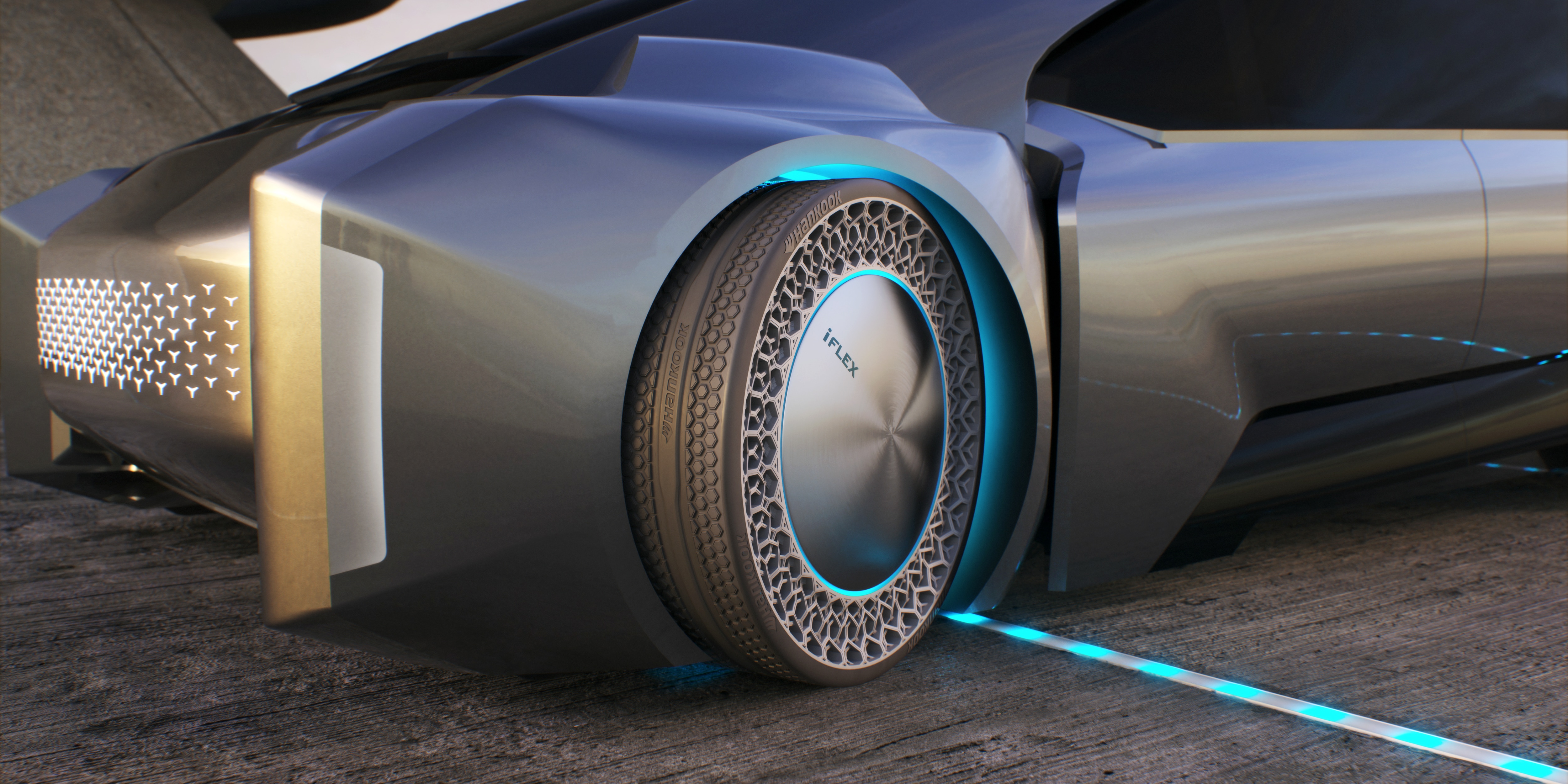

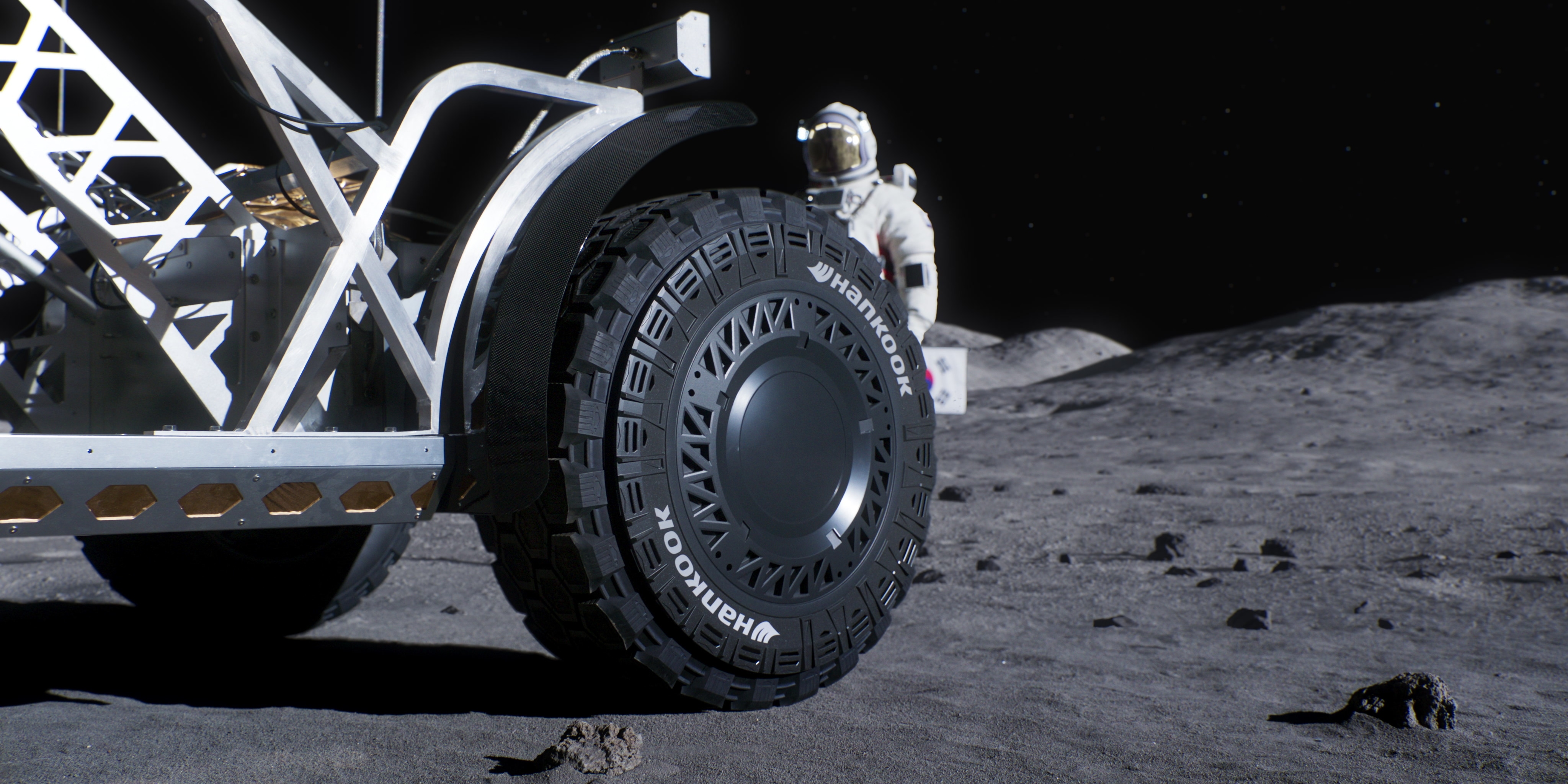

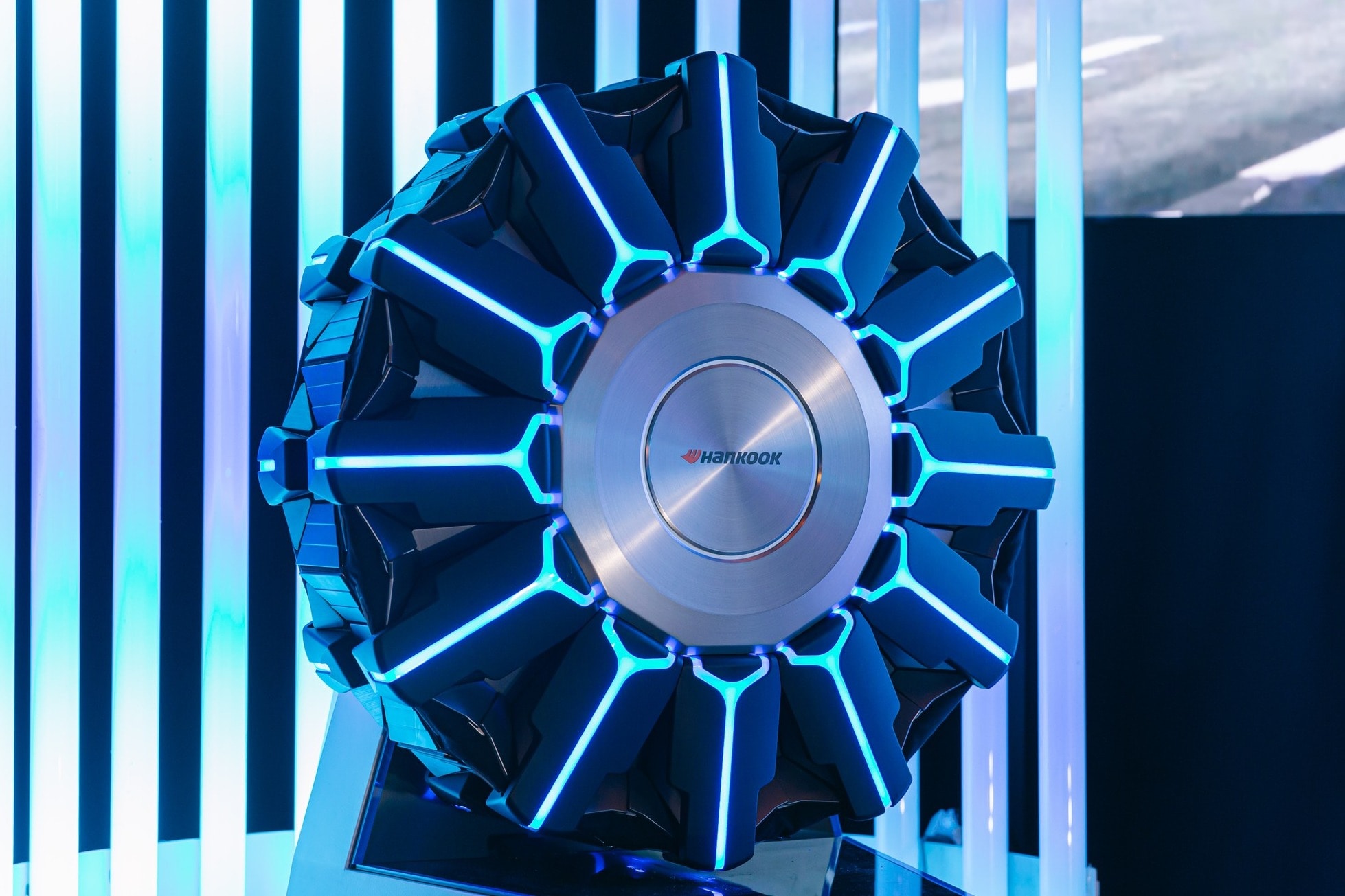

Ventus maintains a comfortable ride even in extreme situations